رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

Abstract: In recent years, the load following capability of thermal power plants has been actively researched, as power system interconnection unavoidably brings about complicated load variations. The key to improving the load following capability is the control of the fuel

More

2015.11.1 Medium speed mills constitute the largest number of mills used for pulverizing coal in a thermal power plant. These mills include bowl mills, roller mills, ball

More

2020.3.2 Coal firing is one of the main processes in a thermal power plant and it consists of several stages. The coal is transported from a bunker through dosers and

More

2023.12.29 Coal blending optimization in thermal power plants based on multi-strategy fusion multi-objective particle swarm optimization. Jun Li. , Fulong Yi. , Yuhua

More

In order to prevent the abnormal operating condition of coal mill in time and effectively, reduce the economic loss of thermal power plants and improve the maintenance system

More

2018.9.24 speed vertical spindle mills are employed in thermal power plant for this purpose. The milling system is an important. part of the auxiliary equipment of a coal

More

2018.12.12 Abstract Pulverised coal preparation system (Coal mills) is the heart of coal-fired power plants. The complex nature of a milling process, together with the

More

2011.4.30 Improved coal grinding and fuel ow control in thermal power plants. Piotr Niemczyk Jan D. Bendtsen. Department of Electronic Systems, Aalborg University, Fr.

More

2023.1.1 Two-stage approach for enabling real-time coal change detection and coal classification in thermal power plants. • Semi-supervised cascaded clustering for

More

2013.11.19 Co-firing of biomass with coal in thermal power plants: technology schemes, impacts, and future perspectives. Emmanouil Karampinis, Panagiotis

More

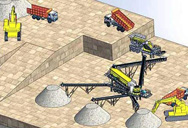

The above diagram shows the simplest arrangement of Coal fired (Thermal) power plant. COMPONENTS OPERATION Main parts of power plant are: 1. Coal conveyor 2. Stoker 3. Pulverizer 4. Boiler 5. الحصول على السعر; COAL BASED THERMAL POWER PLANTS: BOWL MILL INTERNALS

More

Contribute to dinglei2022/en development by creating an account on GitHub.

More

2021.3.25 Thermal Power Plant is an electric producing power plant in which fuel (such as coal, liquefied fuel, uranium, and natural resources) is used to generate heat and that heat is further utilized to heat the water to

More

1 天前 Thermal efficiency is defined as the ratio of heat equivalent mechanical energy available at the turbine to the heat energy available at the combustion of coal in the boiler. The thermal efficiency of the thermal power plants is 30% approx. Most of the heat energy (approx. 50%) is wasted in the condenser.

More

Thermal power station - wikipedia.A thermal power station is a power station in which heat energy is converted to electric power.In the nuclear plant field, steam generator refers to a specific type of large heat exchanger used in a.Level and mix it with the incoming coal in fan-type mills that inject the pulverized coal and hot gas mixture into the boiler.

More

Coal Mills Internals In Thermal Plant Coal Mills Internals In Thermal Plant Coal Mill Internals Tira Coal Mill Internal Design, Tirax coal mill internal desig

More

Coal Mills Internals In Thermal Plant. Coal Mills in Thermal Power Plant Mill (Grinding the performance of mill raw coalhgi,tm,size pf fineness rcfeeder calibration pa flow mill operating parameters mill internals condition and tunning Sizes of raw coal Larger the size of raw coal fed to mill, amount of work per unit mass is Coal Mills Internals In Thermal Plant Coal Mill

More

Maintenance Of Coal Mill In Thermal Power Plant. May 20 2021 MILL REJECT HANDLING SYSTEM IN THERMAL POWER PLANT MRHS May 20 2021 Jagarnath Mahato as it is a maintenance valve Pyrite hopper will be provided with level probes and RTD Mill Rejects from coal mill will drop into the Pyrite Hopper through the grid Oversize material will be

More

The Relationship between the Decline of Oxygen and the ... Intensive coal utilization at the plant is a complicated and complex issue. The steam power plant uses low-grade coal (5,100 kcal / kg) as a boiler fuel.The consideration for the use of low-calorie coal is because the boiler setting requires low-grade coal, the coal is cheaper, and the reserves are more

More

2023.9.21 Advanced thermal plants achieve availability exceeding 90%. However, periodic maintenance outages are needed. Coal plant reliability is generally higher than gas plants. Load Following Flexibility. While more suitable for base load supply, thermal plants can respond to load changes through multiple control mechanisms at the cost of lower ...

More

2024.3.25 The global high chrome mill internals (HCMIs) market size was USD 1237.7 million in 2019 and market is projected to touch USD 3481.24 million by 2031, at CAGR of 9.0% during the forecast period. High chrome mill internals (HCMIS) are balls used extensively in thermal power plants and cement because of their ability to crush minerals,

More

In view of the harsh operating environment of the coal mills of thermal power unit and the frequent occurrence of coal mills defects, this paper evaluated the operating status of the coal mills and command whether it was in a fault condition or not. The evaluation and judgement was based on the SIS system of thermal power plant to collect the pulverized

More

2023.8.28 Abstract: In a pulverized coal-fired (PCF) thermal power plant (TPP), mixture of coal, air and gas is supplied into the furnace volume via the mill duct system and coal/air distribution should ...

More

2011.4.30 Department of Electronic Systems, Aalborg University, Fr. Bajers Vej 7C, 9220 Aalborg st, Denmark (e-mail: fpn,[email protected]). Abstract: A novel controller for coal circulation and pulverized coal ow in a coal mill is proposed. The design is based on optimal control theory for bilinear systems with additional integral action.

More

2018.12.12 In thermal power plant, pulverization of coal is carried out by coal mill. Raw coal is moved from the storage to the mill by conveyor mechanism. The type of coal mill envisaged for our model is bowl mill which is shown in Fig.1. Raw coal is introduced near the centre of the grinding table through the coal feed pipe.

More

The main fuel of current thermal power plants is coal. Coal-fired thermal power plants can be broadly grouped into four categories, mainly related to the inlet steam conditions and the level of associated CO 2 emissions: subcritical, supercritical/USC, advanced USC, and CCS fitted. USC technologies of the 600°C-class have already been applied ...

More

2 天之前 In pulverized coal fired boiler,The coal is pulverized to a fine powder, so that less than 2 % is +300 micro meter and 70 – 75 % is below 75 microns. The pulverized coal is blown with part of the combustion air into

More

Coal mill is an important auxiliary equipment of the coalfired power plant, and its status is directly related to the security and stability operation of the unit the coal feed flow into the boilerThe key input to the coal fired power plant is the coal MPS mill use tire type rollers and are called roller detailed types of mills used in power ...

More

Abstract: Coal mills in thermal power units have problems such as harsh operating conditions and frequent failures. In order to prevent the abnormal operating condition of coal mill in time and effectively, reduce the economic loss of thermal power plants and improve the maintenance system of power plants, a coal mill fault warning method based on

More

Shell liners- 600 nos. weight of liners- 60.26 MTBowl Mills These are medium speed Mills. The Mills are designated as XRP-803/ XRP-1003 Where, X – 3 Phase, 50 Hz Supply (Y for 60 Hz supply) R – Raymond (Inventor of the mill), P – Pressurized, 80/100 – Nominal dia. of the Bowl (inches) 3 – Number of the Grinding Rolls.

More

``` sbm coal mills internals in plant(PDF) Hot Corrosion Erosion Problems in Coal Based Power. Hot Corrosion Erosion Problems in Coal Based Power Plants in India and Possible

More

2024.1.1 The crushed coal is then transported to the store yard. Coal is transported to bowl mills by coal feeders. 3. Bowl Mill. The coal is pulverized in the bowl mill, where it is grounded to a powder form. The mill consists of a round metallic table on which coal particles fall. This table is rotated with the help of a motor.

More

A System for Suppressing and Inhibiting Fires in Coal Pulverizer Mills ... quickly preventing dam age. respectively. accumulations of coal pulverized to small particles can Temperatures within coal pulverizer mill internals vary greatly and can reach 700 degrees Fahrenheit during normal operation. accumulations of raw coal that has spilled over ...

More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.